- EAN13

- 9783841790903

- Éditeur

- Univ Européenne

- Date de publication

- 6 mars 2012

- Collection

- OMN.UNIV.EUROP.

- Nombre de pages

- 136

- Dimensions

- 22 x 15 x 0,8 cm

- Poids

- 211 g

- Langue

- fre

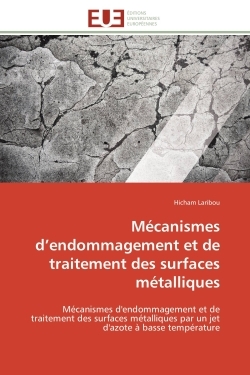

Mécanismes D'Endommagement Et De Traitement Des Surfaces Métalliques, Mécanismes D'Endommagement Et De Traitement Des Surfaces Métalliques Par Un Jet D'Azote À Basse Temp

Hicham Laribou

Univ Européenne

Prix public : 49,00 €

Nitrogen jet have been used recently for matter removal as well as surface treatment. The process consists in projecting onto a surface a low temperature jet obtained from releasing the liquid nitrogen stored in a high pressure tank through a nozzle. This work is aimed at understanding the highly complex jet/material surface interaction mechanisms. Depending on the impacted material, the thermo-mechanical shock and blast effect induced by the jet can activate a wide range of damage mechanisms, including cleavage, crack nucleation and spalling, as well as plastic deformation, void expansion and localized ductile failure. The test parameters (standoff distance, dwell time, operating pressure) play a role in selecting the dominant damage mechanism, but combinations of these various modes are usually present. The main damage mechanism is the decohesion of the material due to thermo-elastic stress generated by the thermal shock. The fragmentation of grains and high-speed transport of nitrogen in a deep layer below the impacted surface and their relationship with the hardening of a surface layer are explored in the case of the steel E24.